A subfield of mechanical engineering known as the dynamics of machinery focuses on the forces that cause or result in the motion of machine components. It deals with analyzing, designing, and controlling mechanisms to ensure efficient, reliable, and safe operation. This field combines principles of kinematics (the study of motion without considering forces) and kinetics (the study of motion with forces) to understand how machines behave under different conditions.

Key Aspects of Machinery Dynamics

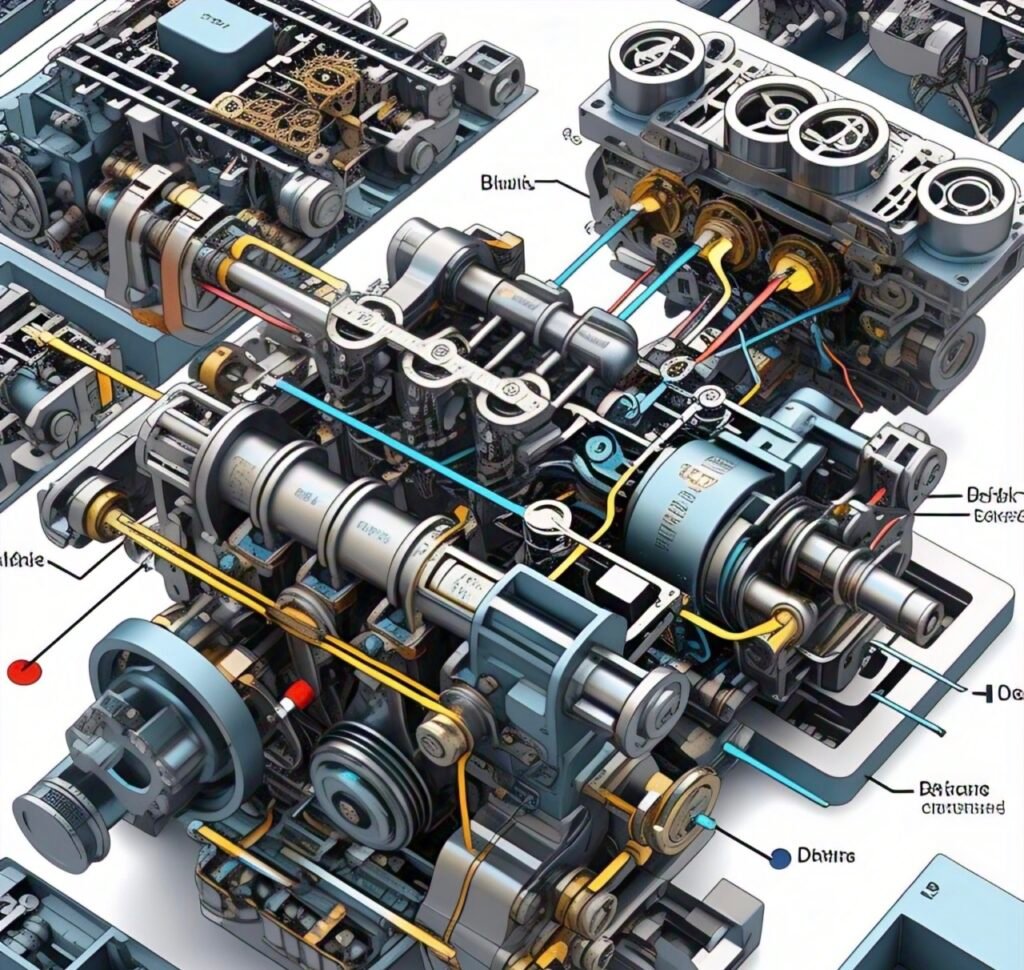

1. Mechanical Kinematics: examines the motion of parts’ geometry without taking into account forces. Involves displacement, velocity, and acceleration analysis of linkages, cams, gears, and other mechanisms.

Example: Analyzing the path traced by a point on a linkage in a piston-crank mechanism.

2. Kinetics of Machines:

Focuses on forces and torques causing motion.

Includes inertia forces, friction, and dynamic balancing of rotating and reciprocating parts.

Example: Calculating the force required to rotate a crankshaft at a certain speed.

3. Force Evaluation: Determines the internal and external forces acting on machine components.

Ensures parts can withstand operational loads without failure.

4. Vibration Analysis:

Studies oscillatory motions of machine parts to avoid resonance and ensure smooth operation.

essential for engines, shafts, and gear systems to avoid fatigue and noise. 5. Balancing of Rotating and Reciprocating Masses:

Ensures even mass distribution to minimize vibrations and wear.

Involves both static balancing (single-plane) and dynamic balancing (multi-plane).

6. Gyroscopic Effects:

Occur in rotating bodies, influencing stability and control (e.g., in flywheels and vehicle wheels).

7. Cam Dynamics:

Analyzes follower motion to ensure smooth and efficient transmission of motion in cam-follower systems.

Applications of Machinery Dynamics

Automotive Engineering: Engine dynamics, suspension systems, and transmission mechanisms.

Robotics: Movement analysis of robotic arms and joints.

Manufacturing Equipment: Ensuring precision and stability in CNC machines and presses.

Aerospace: Vibration control and stability of turbines and control surfaces.

By understanding the dynamics of machinery, engineers can design more reliable and efficient machines, prevent failures, and optimize performance.