Electronic motor design involves the creation of electric motors that convert electrical energy into mechanical energy. Here’s an overview of electronic motor design:

Key Components

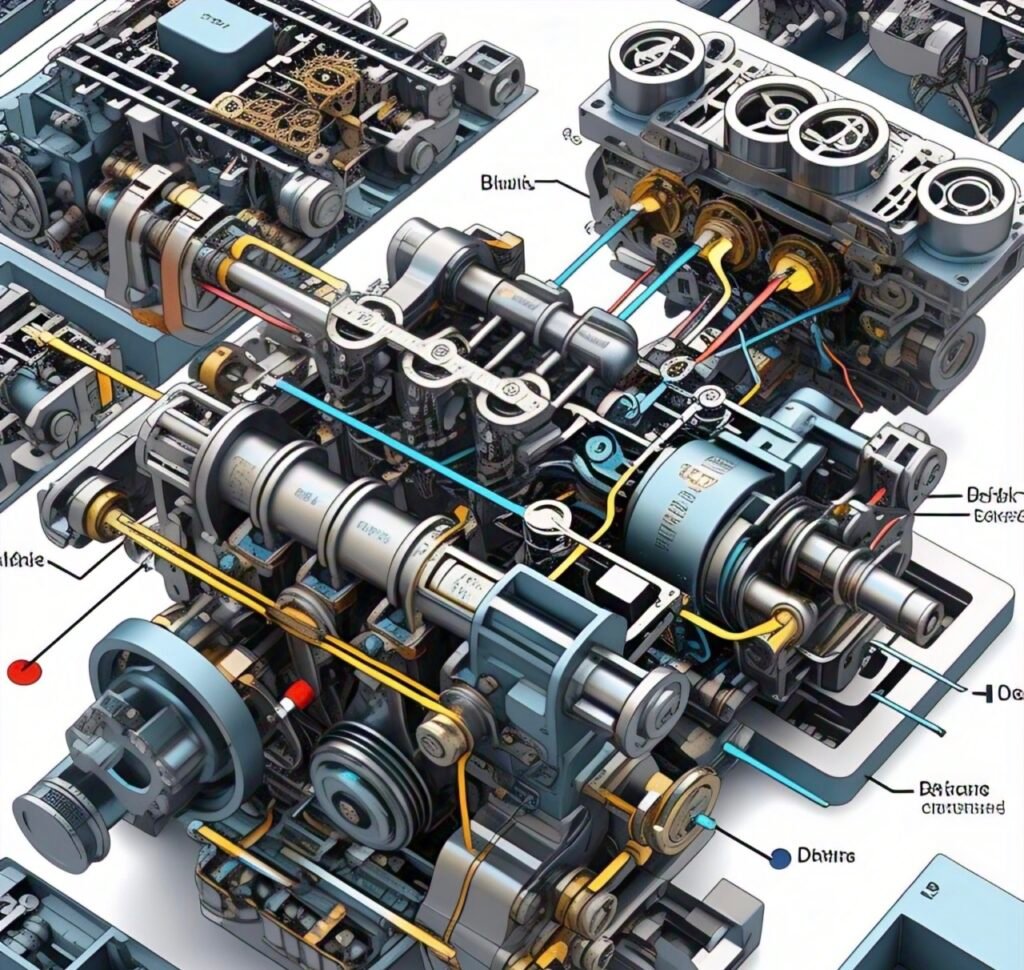

1. *Stator*: The stationary part of the motor, consisting of a housing, windings, and magnets.

2. *Rotor*: The rotating part of the motor, consisting of a shaft, windings, and magnets.

3. Windings are wire coils that carry electricity and produce magnetic fields. 4. *Magnets*: Permanent magnets or electromagnets that provide the magnetic field necessary for motor operation.

5. *Power Electronics*: Devices such as inverters, converters, and controllers that manage the flow of electrical energy to the motor.

Electronic Motor Design Considerations

1. *Efficiency*: Minimizing energy losses to optimize motor performance and reduce heat generation.

2. *Power Density*: Maximizing power output while minimizing motor size and weight.

3. *Torque and Speed*: Designing the motor to provide the required torque and speed for the application.

4. *Thermal Management*: Managing heat generation and dissipation to ensure reliable motor operation.

5. *Noise and Vibration*: Minimizing noise and vibration to ensure smooth and quiet motor operation.

Types of Electronic Motors

1. *DC Motors*: Use direct current (DC) to generate magnetic fields and produce torque.

2. *AC Motors*: Use alternating current (AC) to generate magnetic fields and produce torque.

3. “Stepper Motors” rotate the motor in discrete steps by applying an electrical pulse sequence. 4. *Servo Motors*: Use feedback control to precisely control motor position, velocity, and torque.

5. *Brushless DC (BLDC) Motors*: Use electronic commutation to eliminate brushes and improve efficiency and reliability.

Electronic Motor Design Tools and Software

1. *Finite Element Analysis (FEA)*: Software such as ANSYS, COMSOL, and JMAG to simulate and analyze motor performance.

2. Software like SolidWorks, Autodesk Inventor, and CATIA are used in “Computer-Aided Design” (CAD) to design and model motor components. 3. *Motor Design Software*: Software such as Motor-CAD, MotorSolve, and PSIM to design and analyze motor performance.

Applications of Electronic Motors

1. *Electric Vehicles*: Electronic motors are used in electric vehicles (EVs) to provide propulsion.

2. *Industrial Automation*: Electronic motors are used in industrial automation applications such as robotics, conveyor systems, and pumps.

3. *Aerospace*: Electronic motors are used in aerospace applications such as aircraft propulsion, satellite systems, and spacecraft.

4. *Consumer Appliances*: Electronic motors are used in consumer appliances such as refrigerators, air conditioners, and washing machines.

Future Developments in Electronic Motor Design

1. *Advanced Materials*: The use of advanced materials such as rare-earth magnets, high-temperature superconductors, and advanced composites.

2. *Increased Efficiency*: The creation of motor designs that are more energy efficient, such as those that make use of advanced winding configurations and magnetic circuits that are optimized. 3. *Integration with Power Electronics*: The integration of motor design with power electronics to optimize performance, efficiency, and reliability.

4. *Additive Manufacturing*: The use of additive manufacturing techniques to create complex motor components and optimize motor design.

Related Stories

March 11, 2025

March 11, 2025

March 8, 2025